Material science company Pangaia has partnered with Infinited Fiber on a multi-year agreement to scale the Infinna material technology that turns post-consumer waste into textiles. Innovative materials typically struggle to scale, with fashion brands in particular unwilling to be the first to take the plunge.

The reasons materials struggle to scale are various, from the high cost of scaling to a lack of consumer adoption. However, brands like Pangaia could provide the ideal connection between one and the other. For its part, Pangaia operates a discovery platform, called Pangaia Lab, which is focused on testing future technologies in the consumer market. Craig Smith, Pangaia’s research and development director, said the brand’s goal is to demonstrate that it’s possible to commercially launch high-tech products. “Once the industry sees it is possible to bring materials science innovation to life, this can encourage broader adoption and the technology can scale,” Smith said.

The company also manages a B2B platform called Pangaia Science that helps scale the technologies coming out of laboratories that other brands aren’t familiar with — yet. It uses the popular idea of “drops” to test interest, along with marketing support to call attention to the launches.

“Pangaia Lab is a springboard for the most innovative technologies by reducing barriers between laboratories and consumers. This capsule is our third collection created with an innovative outside company. We’ve already seen an incredible response to the first two collections, with multiple products selling out,” said Dr. Amanda Parkes, Pangaia’s chief innovation officer. Dr. Parkes is working with Pangaia Labs to bring more innovations to the consumer market in the coming year.

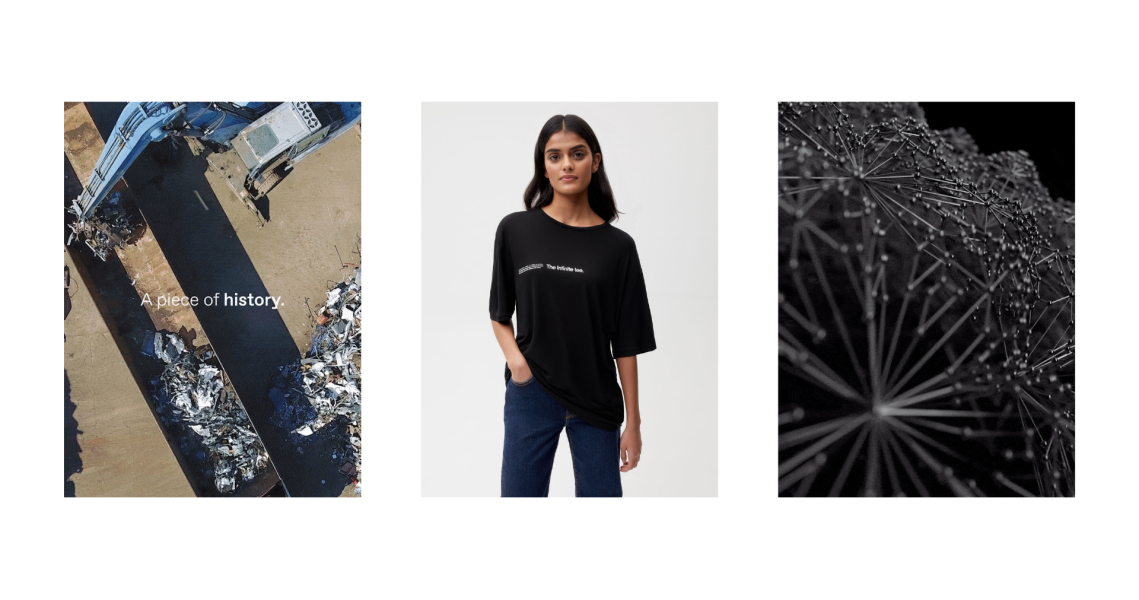

The first product to come out of the Infinited Fiber partnership will be a capsule collection of long- and short-sleeve T-shirts made from 100% Infinna. They’ll be available to buy through Pangaia Lab on April 5. Through Pangaia Science, Pangaia is also promoting the integration of Infinna into its existing products. Infinited Fiber, which became SCS-certified on Monday, will initially be supplying Pangaia with regenerated textile fiber from its pilot operation. Later, the fiber will come from its commercial-scale factory, which is set to be up and running in 2024. In November, Danish womenswear brand Ganni also signed on to use Infinna in its future products.

Infinna is the regenerated textile fiber that has been the focus of Infinited Fiber’s research into material regeneration. It’s meant to be “soft, with the natural look and feel of cotton,” according to the brand. Its creation centers on the cellulose fiber contained in most cotton-rich garments. Kirsi Terho, Infinited Fiber Company’s key account director, elaborated on the process. She said that all discarded textiles are first sorted, and the hard parts like zippers and buttons are removed. The remaining fabric is shredded and then pre-treated to remove things like polyester, dyes and textile treatment chemicals, while also capturing the cellulose in the cotton for further processing. Cellulose forms the basic building block of all plants, and cotton is one of the most cellulose-rich plants on the planet. The next stage, called carbamation, turns the cellulose into a dissolvable powder, which is then turned into a honey-like liquid and wet-spun into brand-new fibers. Finally, the fibers are cut, dried and baled, and can be turned into yarn.

Alternatives for cotton, which accounts for 24% of all fiber used globally in textiles, are few, with cellulose-based fibers forming the vast majority. The cotton industry is still being under-reported and its farming and impact on biodiversity are still unknown. In place of virgin cotton, existing fibers and the Infinna material could be regenerated and used to make new garments.