Multinational consumer goods company Unilever, which owns brands ranging from Dove to premium Tatcha and Hourglass Cosmetics, has used machine learning since the 1950s. Now, it’s developing robotics and AI for use in product testing and development.

Unilever’s beauty and wellbeing arm represents 20% of the company’s annual revenue – in 2022, that equated to $13.3 billion, and sales have been on the rise. The company’s 120,000-square-foot Materials Innovation Factory (MIF), opened in 2017 in partnership with the University of Liverpool in Liverpool, U.K.. is run by over 250 researchers.

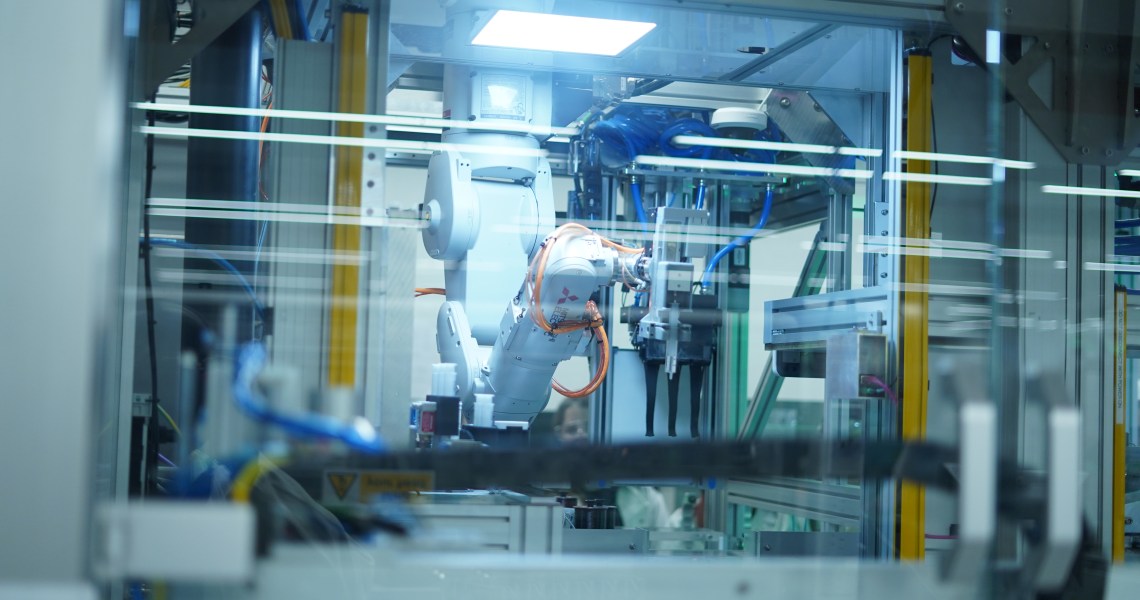

The MIF has been using robots and AI to test and develop its products for the last five years. In 2022, products that were developed using MIF technologies drove one-third of its tech-derived product sales. They included the Dove Intensive Repair Shampoo and Conditioner, the Living Proof Perfect Hair Day Dry Shampoo and the Hourglass Cosmetics Red 0 Lipstick, which were all made with AI and robotics.

MIF’s robots feature celebrity-inspired names, including Ariana, Shirley and Gwen. The Force Brush is a hair brush equipped with sensors for force, temperature and sound. Unilever used it in the development of the Dove Intensive Repair Conditioner to test its ability to detangle hair. The hair brush collects hundreds of data points during the hair brushing process, which translate to insights on potential improvements to be made to product formulas. The Ariana robot, on the other hand, prepares hair samples for widespread lab testing.

“The robots we use in the lab probably exceed the output of three or four people doing the same task,” said Dr. Paul Jenkins, global research director of beauty, personal care science and Technology at MIF. “If a person was doing the same task, it would take them much longer. There are also other complications, like the boredom it would entail after a continuous period, and also the great potential for injury due to the involved repetition.”

The robot Shirley, meanwhile, is stationary and washes hair. Its function is to gauge the user experience and performance of shampoo and conditioner products by Tresemmé, another Unilever brand. It is able to do 120 hair swatch washes in 24 hours. Finally, Gwen, another stationary machine robot, can test up to 96 tubes of Unilever products in 24 hours. It tests and perfects products’ foam volume and density through a process that incorporates water. All the robots exceed human output in these tasks at least fourfold.

Other uses of innovative machines are abundant in the Unilever lab. A rheometer is used to measure the viscosity and acidity of Dove, Sunsilk and Alberto Balsam formulas. It collects 400-500 data points per month. To make the perfect, cruelty-free red pigment for the Hourglass Cosmetics red lipstick, a spectrophotometer was incorporated to measure the pigment’s reflective quality. It took two years to achieve the color without resorting to use of carmine beetles.

The benefits of using robots in a lab setting are obvious. For one, robots can run through the night without experiencing injury due to repetitive tasks. What’s more, they allow for the manipulation of humidity and agitation, as well as speed and force, allowing for thorough trials and experimentation. What’s more, using AI, the data points they provide can be cross-referenced between experiments, increasing the potential for new discoveries and insights.

“We now use AI everywhere,” said Dr. Sam Samaras, global vp of science and technology in Unilever’s beauty and wellness division. “We use AI in our manufacturing plants to make the processes we run more efficient. We also use it to understand the input we get through consumer groups, through active listening and social media. We use it in research whether or not we’re using robotics.”

Unilever is investing in robotics, AI and quantum computing, seeing them as key to the next stage of beauty innovation. It is currently testing three collaborative robots, or cobots, in its Liverpool lab. “The same way that we took the repetitive work of hair washing down to a robot, the cobots will be a more flexible robotic solution versus a fixed robotic solution,” said Dr. Samaras.

The company is also bringing in more stationary robots and plans to incorporate quantum computing when the technology is available for businesses. Quantum computing is an area of computer science that allows for quicker, more complex machine problem-solving, compared to classic computers. It’s based on the physics concept of quantum theory.

“It’s definitely not a replacement for human jobs,” she said. “We hire the best and the brightest scientists from around the Northwest of England, but also all around the world. What AI and robotics allow us to do is have these people do more creative problem-solving and less of the repetitive stuff.”

Working with robots and AI for data also allows the company’s worldwide labs — as far out as Bangalore, India — to monitor each other’s progress using Microsoft lenses or digital camera feeds. “They’re great for efficiencies and cutting out menial tasks,” said Dr. Samaras. “But what really gets me excited is that I get to learn stuff that, 10 years ago, we couldn’t have learned.”